Demo Lift: Difference between revisions

No edit summary |

No edit summary |

||

| Line 21: | Line 21: | ||

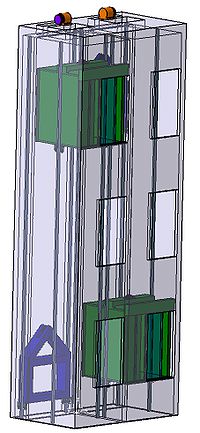

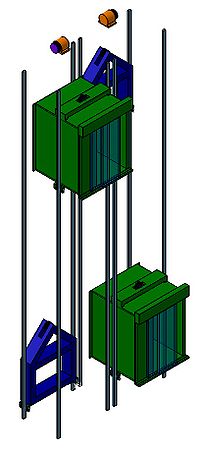

[[File:Gesamtmodell_1.jpg|200px| | [[File:Gesamtmodell_1.jpg|200px|Model overview]] [[File:ohne_Gehaeuse.jpg|200px|Model without housing]] | ||

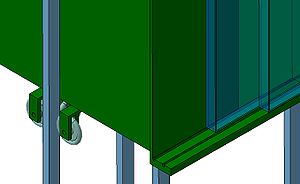

[[File:Fuehrung_Rollensatz.jpg|300px|Details | [[File:Fuehrung_Rollensatz.jpg|300px|Details]] | ||

=Current State of the Project= | =Current State of the Project= | ||

Revision as of 07:35, 2 September 2011

Model lift system with CANopen components

The Heilbronn University is known for many years through congresses and conferences in the field of elevators. Now, a research project is started, that aims at various aspects of the automation of elevators with CANopen, such as compliance testing "in the loop" and the possibilities of telemetry and remote diagnostics. Suggestions and discussions on the project currently come from Mr. Hellmich, Böhnke + Partner, Bergisch Gladbach.

You too could be part of this project!

In order to obtain a realistic test environment, a group of four students from the master's degree courses in Mechanical Engineering and Mechatronics at the Heilbronn University under the direction of Prof. Dr.-Ing. Ansgar Meroth started a project in which an elevator system in 1:10 scale model is built and controlled via original CANopen components. All components are simultaneously simulated by a corresponding function in Vector CANoe and MathWorks Matlab / Simulink models, allowing to replace components in real time by simulated functions.

The resulting model system shall demonstrate the CANopen standards and provide an opportunity to review new components for conformity. It differs fundamentally from a previous model, designed in the MG lift, by a higher mechanical detail. With its open architecture, a combination of both demonstrators is possible.

Model

The objective of the model is to construct and build an elevator system in 1:10 scale. The model will show two shafts, each with three floors and a cabin per shaft. The functionality will correspond as far as possible to the actual features of real elevators. However, due to the miniaturization and the better handling all control panels and control units are not directly attached to the model, but separated in a separate cabinet.

Since the use of this model to fairs and exhibitions is possible and desirable, as many components will be provided with windows or transparent to allow a better insight. Furthermore, the model will be secured, so that visitors can not touch moving parts or electrical components. To permit the use at exhibitions, the model will be transportable. This leads to additional demands on the model. The model with dimensions of 1200 mm x 600 mm x 400 mm (HxWxD) is transportable. Consequently, splitting of the model and securing the movable parts is guaranteed.

Control Units and Network

All control units used in the demonstrator should be or as far as possible match original equipment of real lifts. They are networked via CANOpen Lift protocol.

The project additionally aims at a simulation of the model with all control units with Vector CANoe and MathWorks Matlab/Simulink. By watching the CAN signals in the demonstrator, both programs shall reflect the state of the system. Furthermore, additional control messages arise from the simulation. Thus, additional components or a third shaft may be simulated. In a follow-up project, remote diagnosis is planned.

Current State of the Project

Currently, the design of the system with CATIA V5 R19 by Dassault Systèmes is going on.

Simultaneously, the Matlab/Simulink and CANoe models are built.

Sponsors

Because some components of the elevator model are very expensive, especially the electronic components,you are kindly invited to contribute with your products. We will attach your logo at a prominent place on the model to indicate you as a sponsor.

The following companies already contribute to the model: SICK AG (light curtain model for fusing)

... To be continued with your help ....

If you are interested in becoming a sponsor, please contact Mr. Meroth at the following address: ansgar.meroth (at) hs-heilbronn.de